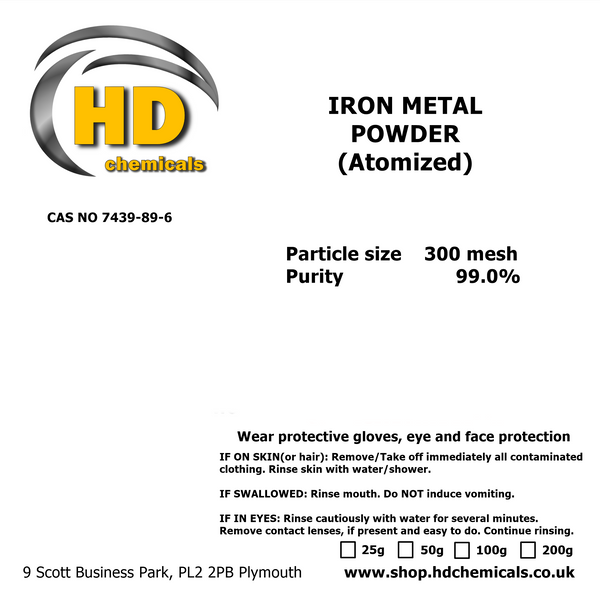

Iron Metal Powder (Atomized)

High purity atomized iron metal powder ideal for cold cast resin casting to create authentic solid metal finishes. Finished castings replicate the appearance and weight of real iron, can be polished or patinated, and easily produce realistic rust effects. A cost-effective and faster alternative to traditional foundry casting.

Key Features

-

Fine 300 Mesh Iron Powder – Excellent surface detail and dispersion

-

Atomized Particle Structure – Consistent quality and strong resin bonding

-

High Purity Iron (>99.0% Fe) – Reliable and repeatable results

-

Real Metal Effects – Can be polished, patinated, or rusted

-

Supplied in 100g Bags – Easy measuring and handling

Uses

-

Cold cast resin casting (iron effect finishes)

-

Decorative sculptures, plaques, and ornaments

-

Rust and antiquing effects for prop making

-

Artistic, craft, and sculptural projects

-

Educational, experimental, and R&D applications

📋 Product Details

-

Weight: 100g – 500g

-

Packaging: Supplied in multiple 100g sealed bags

-

Form: Fine atomized metal powder

-

Particle Size: 300 mesh

-

<2% +75 micron

-

<20% +45 micron

-

-

Purity: >99.0% Fe

-

Impurities (Max):

-

Sulphur: 0.02%

-

Carbon: 0.01%

-

Oxygen: 0.15%

-

-

Bulk Density: 2.8 – 3.0 g/cm³

-

Colour: Dark silver-white to grey

-

Odour: Odourless

-

Formula: Fe

-

Melting Point: 1371 – 1483 °C

-

Boiling Point: 2850 – 3150 °C

-

Brand: HD Chemicals LTD

Step-by-Step: 5 Popular Uses & How to Apply

1️⃣ Cold Cast Iron Resin Casting

-

Measure 100 ml resin

-

Add 100 ml iron powder (1:1 by volume)

-

Mix thoroughly

-

Pour into mould and allow to cure

⚠️ Wear gloves and a dust mask

2️⃣ Enhanced Surface Metal Exposure

-

Lightly dust mould with 5–10 g iron powder

-

Pour mixed resin

-

Demould after curing for higher surface metal content

3️⃣ Rust Effect Finish

-

Abrade cured surface lightly

-

Apply water evenly

-

Leave exposed to air until rust forms

-

Seal if required

4️⃣ Polished Metal Finish

-

Burnish cured surface with fine abrasive pads

-

Buff to desired sheen

-

Optional clear coat for protection

5️⃣ Artistic & Prop Making

-

Adjust powder ratio above or below 1:1 as desired

-

Cast unique textures and finishes

-

Apply patinas or antiquing solutions

📈 Other Names

Iron Powder 300 Mesh, Atomized Iron Powder, Iron Metal Powder for Cold Casting, Rust Effect Iron Powder, Decorative Iron Powder, Metal Filler Iron Powder

❓ Frequently Asked Questions (FAQ)

❓ Is this iron powder suitable for cold casting?

Yes, it is specifically ideal for cold cast resin applications.

❓ What mix ratio is recommended?

A 1:1 ratio by volume (resin to powder) is recommended, but can be adjusted.

❓ Can this produce real rust?

Yes, simply abrade the surface and apply water to create genuine rust effects.

❓ How is the powder supplied?

Quantities from 100g–500g are supplied in multiple sealed 100g bags.

❓ How should iron powder be stored?

Store sealed in a dry place to prevent premature oxidation.